Wind power is an important source of renewable energy that can help reduce greenhouse gas emissions and provide communities with clean, reliable and affordable electricity. Wind is a free and inexhaustible resource, and harnessing it to generate electricity can help reduce dependence on fossil fuels and reduce the amount of pollution that is released into the atmosphere. Wind power offers a cost-effective way to diversify energy sources and increase energy security. It can also help create jobs, stimulate local economies and reduce electricity costs for consumers.

How wind power is converted into electricity?

Wind power is converted into electricity using a wind turbine. Wind turbines work by using blades to capture the wind’s kinetic energy. This kinetic energy is then converted into mechanical power which is used to turn an electrical generator, producing electricity.

Meet the Wind Turbine

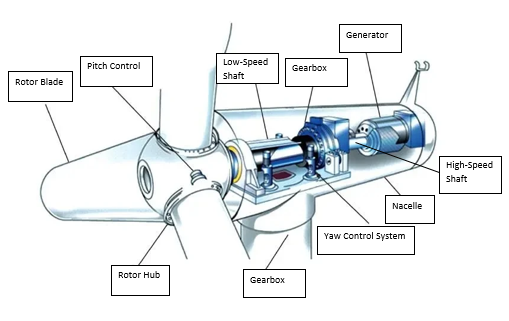

A wind turbine is a device that converts the kinetic energy of wind into electrical energy. It consists of a tower, blades, a generator, and a gearbox. The blades rotate in the wind, capturing the kinetic energy and turning it into rotational energy. This energy is then transferred to the generator, which converts it into electrical energy. The gearbox is used to increase the rotational speed of the blades to match the speed of the generator.

Major Components of Wind Turbine

- Rotor

The major component of a wind turbine is the rotor. It consists of blades attached to a hub, which is connected to the main shaft. The blades capture the kinetic energy of wind and convert it into rotational energy that is then transferred to the generator to produce electricity.

Early-age blades use a NACA airfoil shape (NACA44XX,NA-CA23XX,NACA63XX, and NASA LS), however, these blades are sensitive to contamination on the blade edges which may change blade aerodynamic properties and reduce efficiency significantly. Later, special airfoil shapes are developed for wind turbine blade, such as SERI and NREL series from U.S., RISO-A series from Denmark, FFA0W series from Sweden, and DU series from the Netherlands.

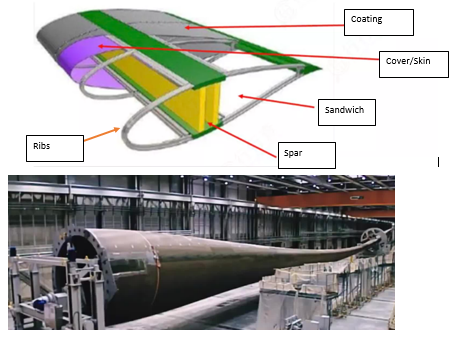

The most important factor in the design of a wind turbine rotor is the overall efficiency of the turbine and the ability to capture the most energy from the wind. Important factors to consider include blade shape, number of blades, blade length, blade pitch, and blade material. Additionally, the rotor must be designed to minimize noise and vibration, as well as withstand extreme weather conditions.

Various types of materials have been used to build turbine blade in history which include wood, aluminum, fabric, and steel. Nowadays, modern wind turbines prefer to use resin composites as major building materials. Resin reinforced with glass fiber or carbon fiber is strong, tough, and lightweight.

- Gearbox

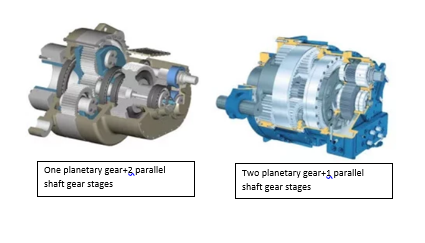

Since the speed of the rotor blade is very low, it is far below the speed required by the generator for power generation, so it must be realized through the speed-up effect of the gearbox gear. Therefore, the design and manufacture of speed-up gearboxes are very critical. At the same time, due to the limitation of its working environment, the wind turbine speed-up gearbox requires a small size, lightweight, and reliable design, which should have a low failure rate. Most of the gearboxes combine planetary gear and parallel shaft design.

For wind turbines below 2 MW, the common arrangement of gears is one planetary gear stage plus two parallel shaft gear stages. For the turbine with more than 2.5 MW, two planetary gear stages plus one parallel shaft gear stage are used.

- Generator

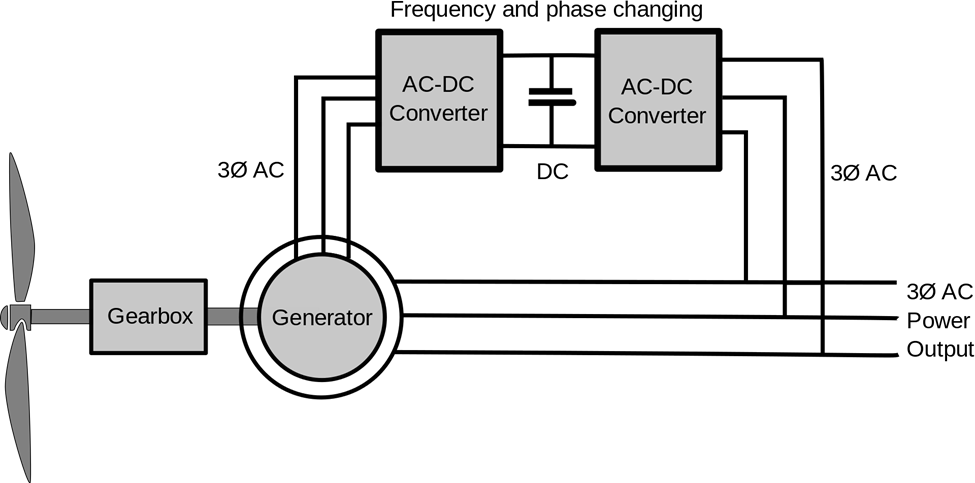

Wind turbines typically use an induction generator, which is a type of asynchronous AC generator that is driven by the rotor of the turbine. Modern wind turbine use doubly-fed induction generators. The advantage of a doubly-fed induction generator is that it allows for the independent control of active and reactive power, which is not possible with a conventional induction generator. This means that it is possible to adjust the power output of the generator to meet the demand of the system, while still maintaining the desired voltage and frequency. Additionally, the doubly-fed induction generator has a higher efficiency than a conventional generator, as it does not require the use of a slip ring for reactive power control.

- Yaw Control

The yaw control systems in wind turbines are to quickly and smoothly align the wind direction when the direction of the wind direction changes, so that the wind rotor can obtain the maximum wind energy.

Small and micro wind turbines usually use the tail rudder to face the wind. It is installed on the tail boom parallel to or at a certain angle with the wind wheel axis.

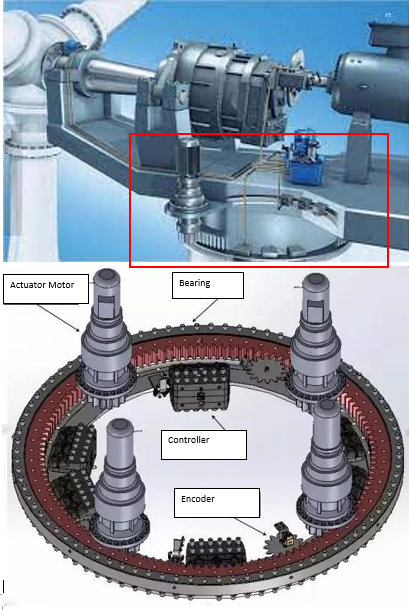

Large and medium-sized wind turbines generally use an electric yaw system to adjust the wind rotor and align it with the wind direction. The yaw system generally includes a wind vane that senses the wind direction, a yaw motor, a yaw planetary gear reducer, a yaw brake (yaw damper or yaw caliper), a large gear of the rotary body, etc. The wind vane is used as a sensing element to transmit the change of wind direction to the processor of the control loop of the yaw motor. After calculation, the processor sends a clockwise or counterclockwise yaw command to the yaw motor. The actuator motor will act on the large gear of the rotating body to drive the wind wheel to yaw against the wind. When the yaw process is completed, the wind vane loses the electrical signal and the motor stops working, the yaw process ends.

- Pitch Control

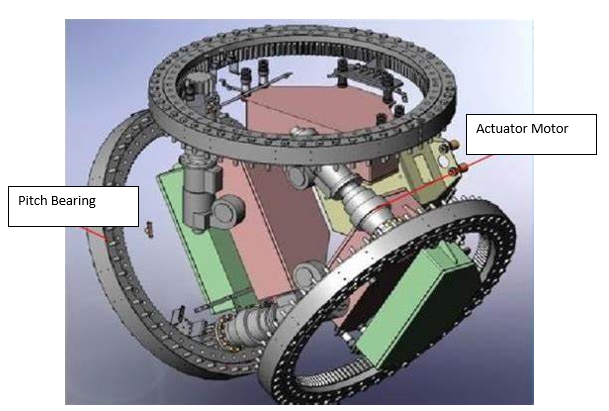

In big wind turbines, which are prevalent, the pitch control regulates the position angle of the blades with respect to the spinning plane. The pitch controller controls the pitch angle of the blades so that the fan can acquire stable power at various wind speeds and protects the fan from overspending when the wind speed is too high. The pitch controller continually checks the wind speed and generator output.

Pitch control can be achieved through either electrical pitch control or hydraulic pitch control.

The mechanism for electrical pitch control is relatively small and dependable. It does not have the hydraulic pitch system’s highly intricate complexity. However, due to motor overheating, its output is insufficient for high-power wind turbines.

Hydraulic pitch control systems use actuators to push the blades to rotate and alter the pitch angle of the blades. Due to its benefits of fast reaction frequency, huge torque, and integration, this mechanism is widely utilized and is particularly suited for large-scale wind turbines.

What makes the offshore wind turbine special?

Onshore wind turbines are typically smaller and produce less power than offshore turbines, but they are much cheaper to install and maintain. Offshore turbines, on the other hand, are much larger and can produce significantly more power than onshore turbines, but they are much more expensive to install and maintain.

Offshore wind turbines need to be installed on special foundations. The foundation is designed to support the turbine, anchor it to the seabed, and transfer the load of the turbine to the seabed. The foundation can be either monopile, jacket, or floating. Monopile foundations are the most commonly used and consist of a single steel cylinder which is driven into the seabed. Jacket foundations are constructed from steel piles that are connected by braces and a steel structure. Finally, floating foundations are used for deeper water, and are constructed from steel, concrete, or a combination of both.

The strength of the wind determines how efficiently the wind turbine operates. In general, the wind at sea is stronger than the wind on land. The wind turbines on land are placed high to take advantage of the comparatively strong wind at high altitudes since the topography on land is undulating, which has a tremendous slowing impact on the wind speed on the ground. The wind speeds on land, however, vary significantly at different heights because of terrain-related issues. Large shifts in wind speed in the vertical direction add a big bending moment to rotor shaft and makes the transmission system vulnerable to damage. At sea, there is no such issue. At sea level water surface is generally flat, with little to no wind resistance, so there is less wind shear than on land, Additionally, the frequency of changes in wind direction at sea is less than on land. Hence, the working environment for wind turbines is very smooth.

The wind turbine’s output is proportional to the cube of the wind speed. About 20% more wind speed occurs offshore than on land. As a result, with the same power output capacity, offshore wind turbines may generate 70% more annual power than those on land.